Estimated reading time: 5 minutes

Creating new possibilities for water reuse, this Texas A&M professor’s lab is perfecting techniques for treating water byproduct from oil and gas production

More Information

Want to get txH20 delivered right to your inbox? Click to subscribe.

Hydraulic fracturing for oil and gas extraction produces water laced with high levels of salt and chemicals. This byproduct is old news in Texas, the top oil-producing state in the United States.

What is a newer concept is cleaning and treating that water from the hydraulic fracturing process and the possibilities it opens for water reuse in the oil industry, nonconsumptive agriculture and more.

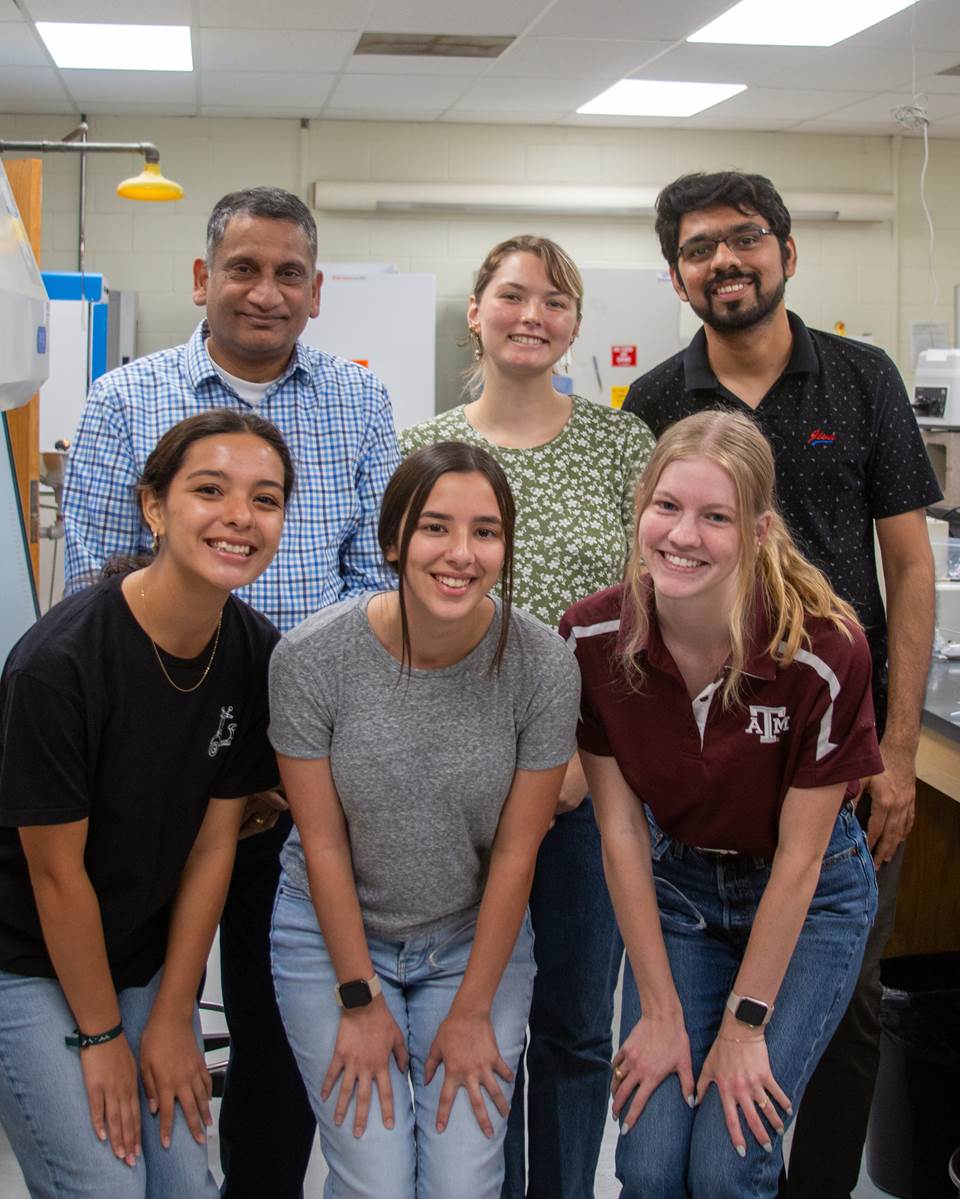

Shankar Chellam, Ph.D., a professor in Texas A&M University’s Zachry Department of Civil and Environmental Engineering, and his students are at the forefront of the produced water research field, expanding on and refining the process of cleaning the toxic water byproduct.

Solving an underground problem

What exactly is produced water?

“Produced water is the wastewater that comes out of oil exploration and production activities,” Chellam said. “A long time ago, there used to be only ‘conventional’ produced water before the increase in hydraulic fracturing, or fracking. In the Permian Basin, which is the world's largest site for unconventional shale oil production, the quality and quantity of produced water are different.”

The process of hydraulic fracturing uses many unknown chemicals, he explained, making the wastewater produced unsuitable for any direct use and difficult to clean. It is also highly saline because the Permian Basin is an ancient seabed at least 250 million years old.

“We don't know exactly what's in it, and so treatment and purification of that water is that much more complicated,” Chellam said. “I'm told that in the Permian Basin, the amount of produced water that comes out is maybe four times the amount of oil that is produced. And we make a lot of oil, so we make four times larger amounts of water than oil, and this water is extremely saline. We have done experiments with produced water that is around six times more saline than seawater.”

With many unknowns and an abundance of produced water to work with, that’s where Chellam and his lab of undergraduates, graduate students and postdoctoral researchers get involved, working to develop a treatment process that’s as effective as possible.

“A lot of what my research focuses on is three areas, primarily coagulation, flocculation and sedimentation,” said Allison Hughes, a senior environmental engineering student in Chellam’s lab. “In very simple terms, you're aggregating these particles that you want removed with an additive, which is a coagulant, and then they're going to flocculate and just get bigger and bigger so that they're a little bit heavier and can settle. And then we filter that water to remove remaining flocs and have a relatively clear supernatant, and then we do desalination."

“We use aluminum chlorohydrate, or ACH, as our coagulant, that's the chemical that we first inject into the water when it's mixing, and then after a rapid mix, we add an anionic polymer, and that helps make the flocs even bigger than it would have been,” said Nicole Giovannetti, another senior environmental engineering student in the lab.

The process by which the polymer works is called inter-particle bridging, which makes the particles larger and helps them settle to the bottom of the container faster. The lab is developing ways to complete this treatment and remove solids in ultrashort times, only about five to 10 minutes, to reduce system footprint.

After removing these larger particles, the team can then filter and desalinate the water, which is the final step of their treatment process.

While the treated water is much cleaner, it may still be unsuitable for human use, Chellam said. Potential uses for the treated water include additional hydraulic fracturing, dust suppression, steam generation and irrigation for agricultural crops not for consumption, such as cotton.

“All this is brand new because I don't think there is a one-stop solution for treating produced water,” said Sanket Joag, environmental engineering Ph.D. student. “So, we are making improvements. First of all, we can remove solids to use it for hydraulic fracturing. After that, we can remove some parts of it and see if that can be used for some kind of beneficial reuse such as for agricultural purposes.”

Reuse it or lose it

Currently, oil companies largely dispose of produced water through deep well injection. The process injects the water far into the earth, below aquifers and other groundwater sources, Chellam said.

Subsurface injection voids the possibility of beneficially reusing the water, he said, and this raises some concerns as water supplies experience greater demand, particularly in arid and semi-arid regions.

Concerns have also been raised that the underground pore space could run out and injection wells could lead to potential contamination of groundwater resources and induce seismicity, Chellam explains. Some companies are looking to research such as his lab’s work for solutions to reduce disposal volumes.

“They are trying to do a better and better job in water management,” Chellam said. “They want us to develop robust processes that can handle variations in the water quality so that, at the very least, they don't need to source new water for fracking, like before. If they reuse at least one part, it is saving groundwater, surface water or another source.”

Partnering with the oil and gas industry, Chellam’s lab obtains samples of the raw produced water and tries various treatment methods. Their results are then shared with the partners, who scale up the processes to treat larger amounts of water in the field. Chellam emphasized that his research is truly a partnership with industry engineers and many of his grants and publications are written collaboratively with them.

“The way we design and communicate our results has to be robust,” he said. People do not know how much chemical to add, what chemical to add and when to add. The things that we study, these students have figured out that an anionic polymer is better than a nonionic polymer, and that a certain dose works better than a different dose, and a certain time is better than some other time.”

“We tell the collaborators and companies that these conditions will work, and then they test it in the field, and so far, they tell me that our data are very good, and they can scale it.”

Ultimately, the oil and gas industry and scientists like Chellam and his students are working towards reuse of produced water. Creating additional water from their process instead of removing even more from the hydrological cycle.

“If we really want oil, we should also be responsible for whatever byproducts we are getting with the oil, because we are consuming it,” Joag said. “If we can't well-inject it, if we can't discharge it on the surface, what are we going to do? What if we can reuse it? We are solving the problem of disposal, and we are also reusing it for a beneficial use.”

Explore this Issue

Authors

Cameron Castilaw is a communication specialist at the Texas Water Resources Institute. She works with the communications team to create social media content, write for TWRI’s various platforms and print projects, and find new ways to inform people of TWRI’s mission and programs.